CES 2026: 6 observations on where robotics is heading

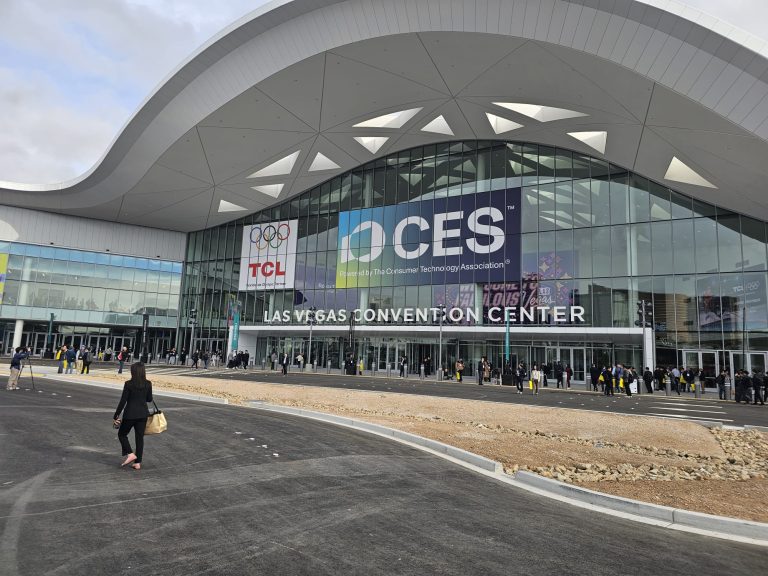

CES in Las Vegas remains one of the biggest moments in the tech calendar, and this year robotics had real momentum. The NextGen Ri team attended to explore the latest products and developments across robotics and the wider tech landscape. We went to benchmark what has moved forward, what is maturing, and what is now ready for real-world deployment.

For anyone unfamiliar, CES is the world’s biggest annual technology trade show, bringing together startups, global OEMs and the companies shaping the next wave of AI, robotics, mobility, smart home, health tech, AR/VR, and display technology. This year, CES attracted over 148k attendees and 4,100+ exhibitors – and yes, there were robots everywhere, in all shapes and sizes.

Here are six observations from CES and what they mean for organisations planning deployments.

1) The big shift wasn’t product reveals. It was readiness.

This year wasn’t dominated by big reveals. The bigger change was maturity. Many vendors have moved beyond prototype-stage demonstrations into deployable platforms with integration options, deployment tooling, and stronger support models. The shift is from “wow” to “ready”. The conversation is moving from capability to operability.

Robotics is entering an operational phase where deployment detail matters more than novelty. Buyers are no longer impressed by the demo. They are asking about uptime, support, and scale.

2) Robotics is moving towards platform thinking

The strongest directional change: platform thinking. Robots are increasingly treated as mobile endpoints for intelligent services, delivering outcomes like:

- inspection and data capture

- logistics and material movement

- manipulation and handling

- security and monitoring

This matters because the value is no longer “the robot”. The value is the full system: robot + sensors + software + cloud, integrated into operating workflows.

3) Teleoperation + AI co-pilots are becoming a serious model

One of the most exciting patterns was teleoperation overlays with AI co-pilots – where human intent guides autonomy in unpredictable environments.

This is a pragmatic approach to autonomy. The robot does more, but a human stays in the loop for the messy parts. What stood out at CES is that hybrid approaches are gaining traction. It is a particularly strong fit for complex, high risk scenarios where control and safety matter, such as search and rescue, hazardous environments, remote operations, and dynamic sites.

4) Public environment ground robotics is accelerating fast

We saw clear momentum around autonomous ground robotics in public environments, such as delivery, security and inspection in spaces where unpredictability is the default.

The hardware now looks far more field-ready. Stability, mobility, sensor capability and overall build quality are improving quickly. The other shift is commercial. Appetite is catching up. There are more serious buyers, clearer procurement conversations, and higher expectations around deployment, support and uptime.

5) Modularity is the route to scale

In this context, modularity means building robotics systems from interchangeable components, such as sensor packs, batteries, compute modules, end effectors, and software capabilities, so teams can configure, upgrade, and service robots without redesigning the whole platform.

That matters because scaling robotics is an iteration game. Performance improves through commissioning, tuning, and updates based on real operating conditions, and modular platforms make those improvements faster and less disruptive. Integrators like NextGen Ri help bring the hardware, sensors, and software stack together, so these systems can be deployed end to end with support and scale in mind.

6) A partner ecosystem model is emerging

Fewer companies are trying to do everything themselves. Instead, deployments are increasingly built as an integrated stack: robot platform + sensors and payloads like cameras and arms + software and AI + integration and support. Even the major players are leaning on partners to turn capability into real customer outcomes.

What this means for NextGen Ri

CES reinforced a shift we’ve been tracking for a while: AI is moving from being primarily software-focused to becoming a hardware reality. Intelligence is leaving the screen and arriving in machines that can sense, move and act. That’s exactly where NextGen Ri sits: helping customers go from capability to deployment, selecting the right platforms, integrating the right stack, and making robotics work reliably in operating environments.

James Brown, Managing Director at NextGen Ri:

“What stood out at CES was the shift from prototype demos to deployable platforms. That matters for customers, and it matters for NextGen Ri. It means better hardware options, smarter stacks, and a stronger partner ecosystem to deliver end-to-end solutions that work in real environments.”

If you’re exploring robotics adoption this year, whether for inspection, logistics, automation or remote operations, we’d love to help you translate what’s possible into something deployable.